Produced by the traditional process of furniture has a very high artistic quality and view and admire a gender, only pure real wood, pure hand carved furniture can highlight craft furniture unique flavor and special value. Below to introduce four kinds of the most classic furniture process:

A, spelling a flower process:

Western royal noble pursuit of 16-17 century sumptuously, celebrities' keen competition ostentation and extravagance, for the interior decoration art provides unprecedented opportunities for development. At this point, the adornment art has not only means "art", more means a kind of "life".

In order to win the favor and orders of the upper class, the artists are so poor, the craftsmen are extremely skilled, and the "Boolean craft", "plain veneer", "Ma Dan paint", "gold foil", "copper relief plate" emerged. A large number of new techniques, such as "ivory inlay", "Chinese and Japanese lacquered skin", and the furniture, which is originally only related to life, is interpreted as an exquisite piece of art. Among the series of crafts, “parquet mosaic” is one of the most widely used and long-lasting processes.

1. Parquet floor: a kind of veneer stitching with different colors and tree species, or a concrete or abstract pattern on the wood, a highly decorative parquet floor becomes the mainstream of the wood floor market, relying on the colorful colors and fine carvings. The craftsmanship and stylish design of the sly have quietly changed the impression of the dullness and indifference that the floor once gave people. On the popular T-stage, it blooms in a new attitude – the parquet floor.

2, parquet door: parquet door is also called flat door, plywood door, mosaic door. The craftsmanship of the parquet door is the surface mosaic (painting) through the environmentally-friendly plant paint, so that the user's artistic creativity can be exerted and the beautiful room door of oneself can be created.

3, stone mosaic: stone mosaic is widely used in the modern building, such as the ground, wall, countertop and other decoration, with the natural beauty of the stone (color, texture, material) plus people's artistic conception "spelling" a frame Beautiful patterns. The popular stone mosaic on the market is also a kind of mosaic.

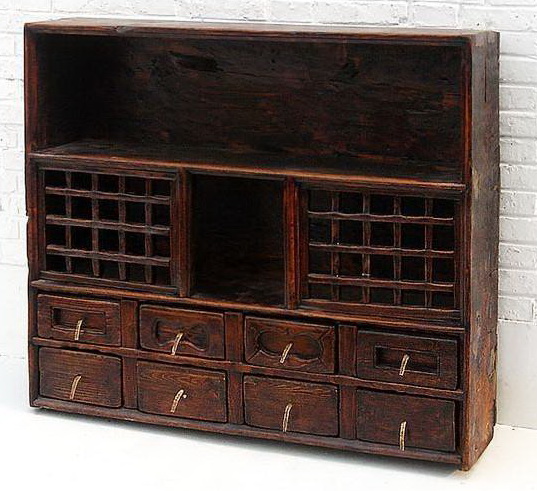

4, parquet furniture: the use of scraps, first made a certain size of small pieces, such as rectangular wood strips, diamond-shaped wood blocks, triangles, rounds, etc., fully dry, planed, and then put together, with cement casein glue or leather glue Gluing, and finally planing and painting. Using small pieces of wood to form a variety of geometric patterns, folded into a variety of desktop, seat, backboard, sitting frame, etc., can be round, not only saves materials, but also economical and beautiful.

5, the production of wood grain parquet

The craftsmen first sketched the surface of the furniture with a pencil, and then separated the individual sealed shapes into paper patterns, such as shell patterns, palm leaves, wood gods, and children's head patterns. Then choose a different piece of wood for each pattern and cut the wood according to the edge of the pattern. At the same time, another group of craftsmen carved the grooves on the surface of the furniture according to the design pattern. A closed shape was fitted with a groove. After the thousands of pieces of wood were made, the chips and grooves were perfectly inlaid.

A clear division of labor ensures that every component and detail is treated with the most professional art. Of course, due to the different shapes of the wood, and the skillful craftsmanship, there is no guarantee that they are 100% tightly stitched. Therefore, the craftsmen need to make the glue (filling the small gap between the wood chips and the wood chips) and sanding after the wood chip is inlaid with this process. Smoothing the entire surface, and finally a clear varnish, so that the texture of the wood is naturally revealed, thus showing the perfection of the entire "flower mosaic" process.

Second, the old process:

Antique old-fashioned crafts are currently used most commonly in the production of American-style furniture, followed by European-style materials with the characteristics of the Renaissance. Chinese-style classical furniture uses some antiques to achieve the effect of imitation of the Ming and Qing dynasties. Old craft.

Antique old work and painting are not falsified; mainly in the processing of the surface of the furniture, the coating is different from the requirements for the production of ordinary products. At present, furniture manufacturers use antique old crafts and paintings as surface coating processes. Compared with ordinary painting, the antique old-fashioned craftsmanship of the furniture surface awakens the beautiful memory from some, and releases the feelings of yearning for nature and returning to nature.

A few years ago, the jeans were deliberately worn out, and nowadays, furniture and decoration also smashed the “old wind”. Old furniture has a sense of vicissitudes in the year, and it is more popular among white-collar and middle-class consumers. Although the surface is old, it is expensive, because the last one is done by hand, and the labor is not cheap. The whole process of furniture is as follows:

1, fever: burning is to make the wood grain more prominent, the wood grain will be exposed when polishing, there is a "broken" feeling. Burning is beneficial, but there are also drawbacks, the wood will crack, the old people generally do not mind cracking, cracking will make the furniture more vicissitudes.

2, polished: after the burn is dark, and then began to polish, after the grinding, the surface of the layer of gray will fall, the wood grain is very obvious, very beautiful.

Tip: If you don't want to do light colors, brush the varnish now.

3, plastering: the next is plastering, said that there will be cracks after burning, this requires putty powder to smooth.

4, color: more putty powder sand will be on the primer, the desk is placed in the children's room, consider the use of light color, the color is Chu Feng on-site adjustment, first use white: adjusted to pour The spray gun is ready to be colored. It takes a certain amount of time for the paint to dry. The polyester paint adds a curing agent, and the sun is shining, and it doesn't let me wait for a long time.

6, smoothing: After drying, start grinding, use a rag to wet the table, with water mill, so the surface will be very slippery. And after grinding, there will be blue and yellow green, much like the color of the set.

7. Upper varnish: After finishing the varnish after grinding, a distressed furniture paint is completed.

Third, the engraving process:

The art of Chinese wood carving crafts can be traced back to the primitive society. At that time, there were many handicrafts that had begun to take shape. In the Warring States Period, the woodcarving process was developed by the Shang Dynasty for the simple engraving of the pottery process and the engraving of the carved plate, and developed into a three-dimensional circular carving process. The wood carvings of the Han Dynasty were made entirely of wood, which pushed the Chinese woodcarving art to a peak. During the Tang and Song Dynasties, the wood carving technique became more and more perfect. The wood carvings of the Ming and Qing Dynasties are the mature era of Chinese classical woodcarving art. The works are very rich, except for animals and people.

1. Yin carving "Yin carving, also known as Yin carving or Shen carving, refers to a technique of concave carving, often in the form of characters, dark octagonal, bat, plum, orchid, bamboo, chrysanthemum, etc. in the screen, plaque And the engraving of furniture such as cabinets.

2, relief: relief, also known as the Yang sculpture, is the product of the combination of sculpture and painting, using compression to deal with the object, relying on perspective and other factors to express the three-dimensional space, and only for one or two sides to watch. The relief is generally attached to another plane, so it is used more on the building and is often seen on utensils. Due to its compact nature and small footprint, it is suitable for decoration in a variety of environments.

Embossed, deep: Round carving, also known as three-dimensional carving, carving, refers to non-compressed, is a sculpture art with three-dimensional space art. The round sculpture is the overall expression of art on the carved piece, and the viewer can see the various sides of the object from different angles.

It requires the sculptor to engrave all the way from front, back, left, right, up, middle and bottom. The techniques and forms of round carvings are also diverse, realistic and decorative, as well as concrete and abstract, indoor and outdoor, on-shelf and large-scale city sculptures, colored and non-colored, etc.; sculpture content The subject matter is also colorful, it can be a character, an animal, or even a still life; the material is more colorful, with substance, wood, metal, clay, textile, paper, plant, rubber, and so on.

4. Openwork: In the relief work, the convex object part is retained, and the background part is partially or completely hollowed out, which is called openwork (openwork carving). Openwork is a technique that hollows out the base of a flower board. It usually engraves only the outer surface of the object. Because this kind of engraving will hollow out the bottom, it can produce a kind of vision that crosses the wooden feeling, with the embossed spirit. The openwork in pure sense is completely cut out with a shackle, and is often treated with rough textures at home.

The back of the openwork is mostly expressed in the form of a screen, and there are single-sided openwork and double-sided openwork. The single-sided openwork is only engraved on the front side, and the double-sided openwork engraves the image on both sides of the front and back.

5, transparent double-sided carving: transparent double-sided carving, is a kind of openwork, is to use a pattern, both sides of the front and back carving, both sides can appreciate the same pattern, novelty and lovely, similar to Suzhou's double-sided embroidery .

There is also a way to sculpt different patterns on the front and back sides of a flower board, and different themes appear. This requires the masters of the sculpture to have superb wisdom and clever ideas. Most of the transparent double-sided carvings are applied to the furniture that can be seen on both sides of the strips, doors and windows, partitions and hangers. There are generally two types: one is the same for the positive and negative patterns, but one is positive and one opposite; the other is the positive and negative patterns are different. The double-faced engraving has a high artistic appreciation value, and even if the whole piece of furniture is scattered, the engraving plate can be collected as a separate art.

6. Tongdiao: Tongdiao is a technique developed on the basis of embossing and engraving tradition. The picture can be multi-layered and overlapped. Therefore, the content of the carving has great capacity and high expressive power. It is a wood carving art form widely used in ancient architecture. Such as doors and windows, skirts, ceilings and columns of halls, etc., the use of relief technology. The simple shape is carved with a simple and elegant pattern and a vivid artistic image, which gives people a pleasing enjoyment.

Fourth, the gold foil process:

In China, gold foil is a traditional Chinese handicraft. It originated from the Eastern Jin Dynasty and matured in the Southern Dynasties. It is popular in Song, Qi, Liang and Chen. Nanjing is the birthplace of Chinese gold foil. Nanjing gold foil has been passed down for nearly 1700 years.

The gold foil is the traditional craft of our country. In the past, the aristocratic class and the royal family liked to use gold jade as their decoration in order to show their noble status. The ancient Chinese have been able to craft craftsmen, and the lifestyles of the emperors and nobles are so eager to promote these craftsmen in gold. Silver processing and application have to be refined, and the exquisite and luxurious gold foil craft and gold foil furniture are born in such a historical background and cultural atmosphere.

Furniture foil gold foil process solid wood furniture stickers gold has been since ancient times, this way of highlighting luxury has been used by people, but nowadays the gold paste process is very different from the original, let us understand the solid wood furniture The steps to paste gold.

1. The gold paste of modern solid wood furniture must first be sanded with wood, wood glue, and plywood frame to remove all the thin wood strips or protruding mud to fill all holes or defects.

2. Prepare the plaster and apply it to the frame with a brush. After a few hours, the plaster surface sandpaper was polished again and covered with a colored varnish. The color of the first layer of varnish can be used to apply a brighter gold foil according to the effect you want. The earth color is used for classical effects, and the white and gray are used for silver foil.

3. The varnish layer applied to the product in the subsequent stage can replace the plaster layer. The catalyzed 0% catalyst and 10-20% polyurethane diluted diluent can be sprayed with a spray gun. Depending on the effect, it can be a different color.

After the coating process is finished, the wood is allowed to dry for about two hours. Any sputum or stucco dripping of the plaster or varnish should be polished when the preparation process is completed.

4, the wood is ready for gluing, we use white water-soluble gold glue. Use a brush to apply the part to be golded. Be careful not to have drops. The viscosity of the glue after application can be maintained for half an hour to twelve hours, and the gold is applied after one hour.

5. In order not to lose the viscosity, do not work in a dusty environment. And protect the treated surface. Once the glue is dry, it starts to stick gold. Gently pick up the gold foil according to the area to be covered, carefully place it on the frame and use a special purpose to ensure that the gold foil coverage is slightly larger than the frame surface. Corners, curves, twists and other parts are attached with gold foil. Excess material is wiped off with a softer wool brush. This also allows the gold foil to be properly secured to the wood.